Finite Element Analysis

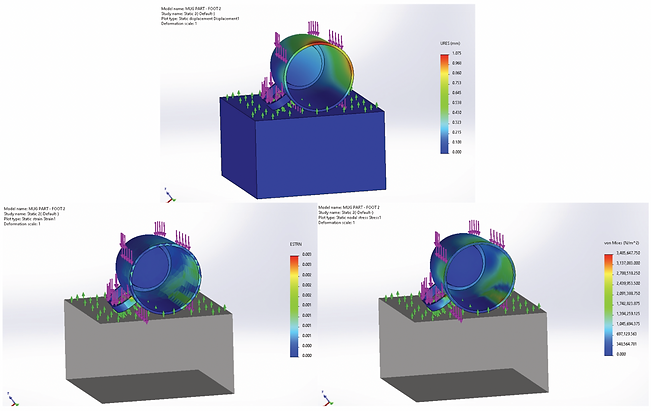

Using SolidWorks models, simulations of worst case scenarios have been run to provide a basis for designs to be evaluated and optimised. FEA analysis was done for a camping mug project, mimicking the scenarios that it had either been stepped on or dropped. Both static tests and drop tests were simulated, demonstrating skill in both.

Scenarios

1 / Static Test 1

95th percentile weight male stepping on mug which is on its side on the ground.

2 / Static Test 2

95th percentile weight male stepping on mug which has rolled on the ground to a stop, resting on its handle.

3 / Drop Test

95th percentile height male dropping mug on hard ground (i.e. concrete).

Static Test 1

Results indicated that only elastic deformation occurs, meaning the material is strong enough the withstand the scenario. This was identified as being due to having the correct balance of material strength and material thickness on the mug.

Static Test 2

Results indicated that the handle 'reinforced' the strength of the mug, indicated by the decrease of stress and strain results in comparison to static test 1. This is due to the stress being shared across a larger area. These results are positive in terms of the design as the mug is more likely to fall in this position rather than the position in test 1.

Drop test

Results indicated that whilst in most angles of being dropped only elastic deformation occurs, in some instances small amounts of plastic deformation occurs. Functionally, this would only result in visual deformation (such as a chip or a dent) but wouldn't prevent the mug from functioning, thus indicating a relatively successful design.